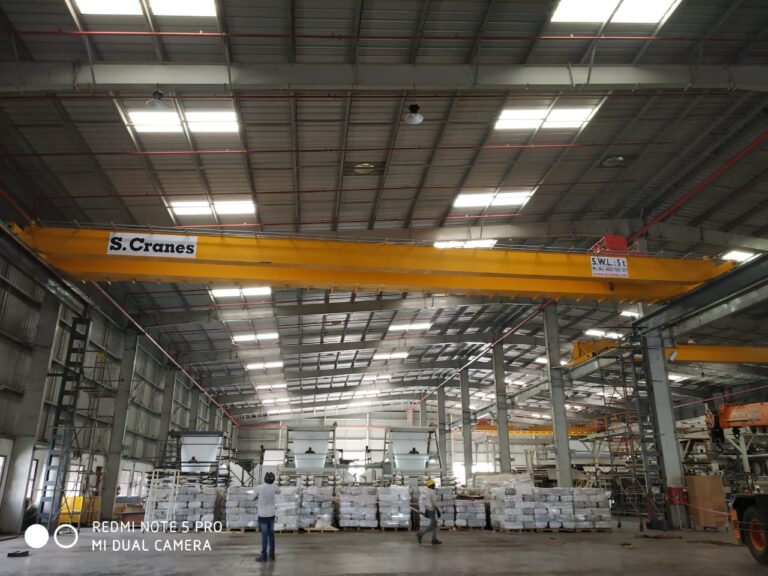

1. Erection of EOT Crane:-

1.1 General:

An E.O.T. crane stands for Electric Overhead Travelling crane. this is used for handling & moving a maximum specified weight of the components called capacity of the crane within

a specified area. the crane can be operated manually or by electric power. electrically operated crane can be divided into different sections as follows:-

(a) Bridge girders,

(b) End carriages,

(c) Hoisting trolley also known as crab,

(d) Long travel machinery,

(e) Driver’s cabin/Floor operation.

Before maintenance of the crane, it is important that some guidance is available to erect the crane to avoid accident & smooth running of the crane.

1.2 Erection of Crane:-

The crane should be erected on an un-occupied floor where no industrial or construction work is to be carried out during erection. The size of the floor must ensure free &

convenient handling of the crane during the erection period i.e. setting the crane in erecting position on the floor, turning the suspended crane etc. the most convenient place for

erecting the crane is the space between the columns provided there are no horizontal bracings connecting the roof trusses. the roof trusses used for lifting the crane should be

checked for stresses during erection with a dynamic factor of 1.2. Besides testing the rope & trusses for strength, they should be tested for stability

under horizontal forces acting at right angle to the truss plane. The winches employed for lifting the crane should be equipped with ratched stops.

The wire rope employed for erection must have tags indicating wire breaking forces & should be free of defects, fractures, kinks etc.

The minimum safer factor should be three.When hoisting the crane or its parts the following conditions should be kept in mind.

(a) The angle of inclination of the slings should not be less than 45º.

(b) To prevent rupture of the rope due to sharp edges of lifted materials, wooden or metal lining should be used.

(c) The number of clamps to be used for fastening the rope should be sufficient.

We should also ensure that the axes of the winch drum should be exactly at right angle to rope direction.

1.3 LIFTING THE CRANE:-

Depending on the weight of the crane, the strength of the rope, trusses, the crane can be lifted by one winch or two or four winches. if the weight of the crane is not

very high the crane structure can be assembled at the floor & the complete crane can

be lifted. in case the crane is very heavy we may lift different portions of the crane in

sequence as follows:-

1. End carriages complete with L.T. wheels fitted in position.

2. Main girders.

3. Hoisting trolley or crab.

4. Driver’s cabin & other electrical components.

To simplify the positioning of the different components the crane should be match marked at every joint. every joint should be bolted only by means of

machine bolts. For the safety of the people engaged in erection work, the following safety rulesshould be observed:-

1. When lifting the crane structure the dangerous zone of assembly must be protected

with flags barriers etc. & no un-authorised person should be admitted in the area.

2. Do not lift the crane if the erection area is badly illuminated.

3. Although the lifted structures should not be allowed to suspend for a long time but in case of exception we must see that:-

(a) The safety factors of the ropes & cross girders should be twice than the normal working.

(b) The last line of rope running off the blocked should be clamped near the block.

(c) In case the load is lifted by means of hand winch, remove the handles, apply & secure the brakes.

(d) Post workers to ensure security.

4. It is strictly forbidden to stand or walk under the crane when the crane is being lifted.

5. The scaffolds must comply with the safety rules. the fitter working on top, must handle the parts & tools carefully so as to prevent them to fall down.

The erection supervisor must ensure that all the components are assembled in accordance to the sub assembly drawings. after the crane has been fully erected,

we must do the electrical connection exactly as per its wiring diagram. before we actually do the load test we must run all the motions in idle condition. during

idle running of different motions we should particularly observe the following:-

(a) Eccentric running of moving parts.

(b) Alignment of shafts.

(c) Fauling of moving components.

(d) Any un-usual noise.

(e) Presence of lubricant at desired surfaces.

After the idle running of different motions & satisfactory performance of motors, limit switches, brakes & controllers we may go ahead with load testing of the

crane in accordance to relevant Indian standards. If the contract for erection & commissioning of the crane is not given to the manufacturer of the crane, it will be desirable to seek their supervision during Erection & commissioning. This will ascertain the alignments of components & thus longer life of the crane.